-

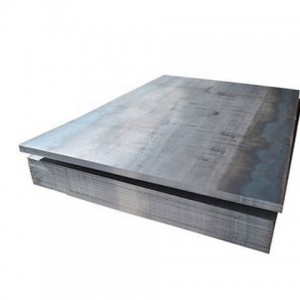

Titaja ti o gbona ms awo / gbona ti yiyi irin irin / hr irin okun okun / dudu didan / dudu irin (s255 S355 q65)

- Ohun elo: awo ti o firanṣẹ, awo ti o wa, ṣiṣe awọn ọpa, ni awọn ọja irin ti o yipo tutu, ṣiṣe awọn irinṣẹ kekere

- Boṣewa: ASTM

- Iṣẹ ṣiṣe: alurin alulẹ, fifun, gige, ti n tẹ, ti n bọ

- Arun awọ: Bẹẹni

- Alloy tabi kii ṣe: ti kii ṣe alloy

- Apẹrẹ: alapin.sheet

- Itọju dada: nu

-

-

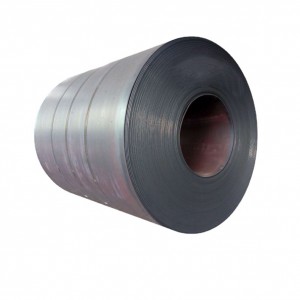

- Sisanra: 1.5-15mm

- Boṣewa: ASTM

- Iwọn: 0.6m-3m tabi bi o ṣe beere

- Gigun: bi alabara ti a beere

- Ijẹrisi: Sàn, Jis, ISO9001

- Ifarada: ± 1%

- Iṣẹ ṣiṣe: alurin alulẹ, fifun, gige, ti n tẹ, ti n bọ

- Arun awọ: Bẹẹni

- Alloy tabi rara: jẹ Alloy

- Akoko Ifijiṣẹ: Laarin ọjọ 7

- Orukọ ọja: Gbona irin ti yiyi

- Dada: Dudu

- MoQ: 1 pupọ

-

Titaja ti o gbona ms awo / gbona ti yiyi irin irin / hr irin okun okun / dudu didan / dudu irin (s255 S355 q65)

- Ohun elo: awo ti o firanṣẹ, awo ti o wa, ṣiṣe awọn ọpa, ni awọn ọja irin ti o yipo tutu, ṣiṣe awọn irinṣẹ kekere

- Boṣewa: ASTM

- Iṣẹ ṣiṣe: alurin alulẹ, fifun, gige, ti n tẹ, ti n bọ

- Arun awọ: Bẹẹni

- Alloy tabi kii ṣe: ti kii ṣe alloy

- Akoko Ifijiṣẹ: 7-10 ọjọ

- Apẹrẹ: alapin.sheet

- Itọju dada: nu

-

-

ASTM / AISI / Sae / JIS A36 SS400 Q35

Iwọn: 1000-4000, ati bẹbẹ

Boṣewa: ASTM, AISI, Jis, GB, Bẹẹni, en

-

-

-

Gbigbe Ile-iṣẹ Irọnu

Sisanra: 4.5mm-300mm

Ohun elo: CCSA, CCSB, CCSD, CCE, DH36, Ah36

-

-

-

Irin okun

Irin okun irin, tun mọ bi okun okun irin. Irin naa gbona ati tutu-tẹ sinu awọn yipo. In order to facilitate storage and transportation, it is convenient to carry out various processing (such as processing into steel plates, steel strips, etc.) The hot steel strip from the last rolling mill of finishing rolling is cooled to the set temperature by laminar flow, and is rolled into steel strips by the coiler. Coils, cooled steel strip coils, according to the different needs of users, through different finishing lines (leveling, straightening, cross-cutting or slitting, inspection, weighing, packaging and marking, etc.) Coiled and slit steel strip products.